| Filling Vessel |

18L standard can(square can) |

| Measuring Range |

2.5~35kg |

| Minimum Indication Unit |

0.01kg |

| Filling Accuracy |

± 20g~50g |

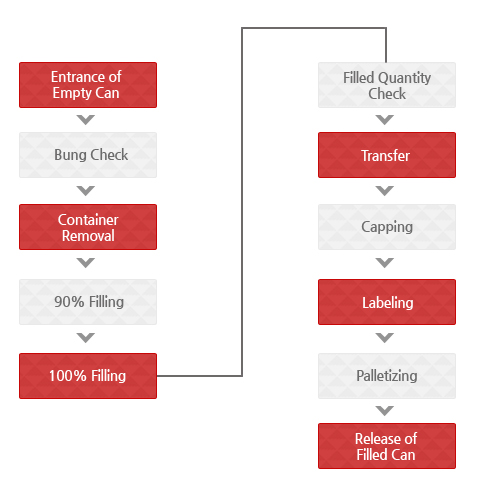

| Filling Method |

Dual control filling |

| Liquid Contact Material |

SUS304(316 also available) |

| Packing Material |

Teflon |

| Cleaning of Filling Valve |

One-touch disassembly and solvent cleansing |

| Drip Prevention |

Drip tray type |

| Loading Capacity of Empty Can |

Standard 10 cans |

| Capping Machine (Optional) |

Royal cap/protector |

| Labeler (Optional) |

Max 160W x 200L |

| Measuring Method |

Load cell |

| Power Supply |

220V, 50/60Hz, 5KVA |

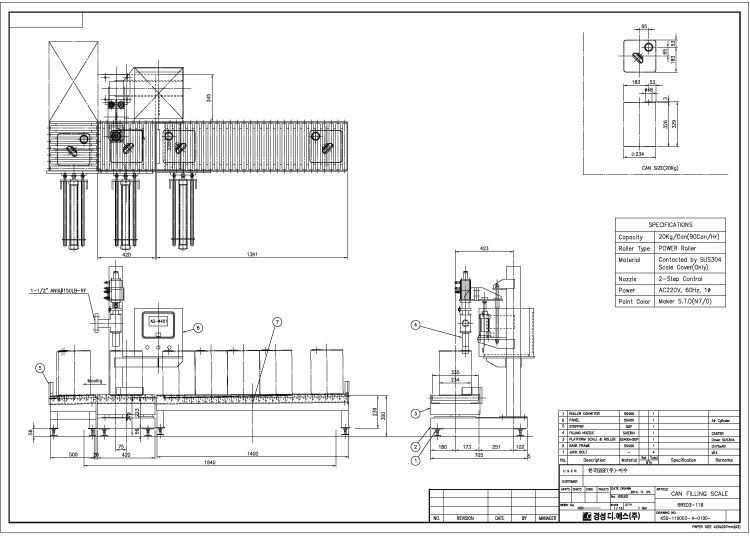

| Air Pressure |

5kg/cm², 400N ℓ/min, 2 heads |

| Machine Weight |

About 1200kg at 2 heads |